Methods of testing soils for engineering purposes

AS 1289.6.2.2-2020 pdf download.Methods of testing soils for engineering purposes

Method 6.2.2: Soil strength and consolidation tests — Determination of shear strength of a soil — Direct shear test using a shear box.

(I) Adjust the shear load measurement system to ensure there is no shear load and take the zero reading of the device used to measure the shear load. Move the measurement mechanism so that slack is taken up and clamp the measuring system in place, ensuring the load reading remains zero.

NOTE 2 If there is proper contact of the shear box with the proving ring or transducer and no slack in the system, then a small movement of the worm drive should produce a small movement of the proving ring gauge, or reading on the load measuring indicator.

(j) Mount the horizontal displacement gauge or transducer in position, making sure that it has sufficient travel available. Set or record the gauge or linear differential variable transformer (LDVT) zero reading.

(k) Place the hanger carefully onto the top loading plate so that the load is transmitted through the spherical ball seat and the seating arrangement on the hanger.

NOTE 3 Sample compression may occur at this stage as the gauge (or transducer) that measures vertical movement is generally mounted on top of the load hanger. The measuring device may bear on the loading cap for a measure of the Initial compression, If needed. If the hanger applies load to the specimen, its mass. mh, should be measured before placing it.

NOTE 4 For devices with counterweighted hangers that do not apply load, the weight of the hanger Is not needed (mh = 0).

(I) Place the vertical displacement gauge or transducer at the centre of the load hanger so that it measures the displacement between the hanger and the loading frame. Ensure that the gauge is set at mid-range to register either an upward or downward movement. Record the initial reading of the gauge.

To minimize the effects of suction for fine-grained soils, where required submerge the specimens by adding water to the carriage so as to maintain the soil in a submerged condition. Check for any vertical movement of the loading cap due to inundation and allow sufficient time for movement to cease.

NOTE 5 For clay soils, swelling under low stress can alter the properties of the specimen. In this instance, ask the client for the recommended normal load at which submerging is to occur. In the absence of such advice, submerging should occur after consolidation is complete at the normal load specified for shearing.

(n) Where required, calculate the mass, mw, to be placed on the hanger to give the required normal stress, a,1, from Equation 5.2:

Where the load is applied through hydraulic or pneumatic means the system shall be calibrated to determine the relationship between stress and pressure. In these systems, a load cell shall be used to determine the load transmitted to the top plate.

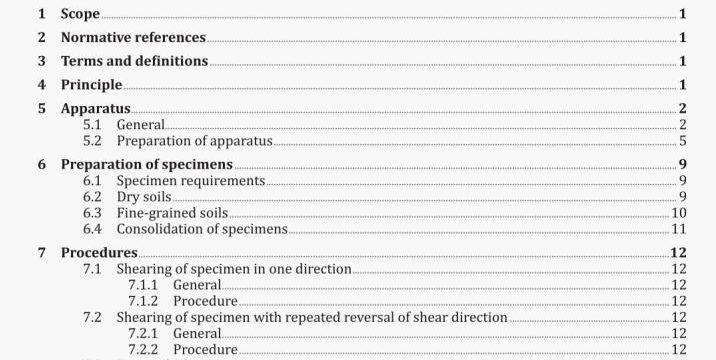

6 Preparation of specimens

6.1 Specimen requirements

The specimen height shall be between 30 % and 50 % of the specimen length. The heights of the specimen in the two halves of the box should be approximately equal.

The maximum particle size In the soil to be sheared shall be less than or equal to one-tenth of the initial height of the specimen. if the specimen is well graded (C > 6 and 1 <C < 3), the maximum size shall be less than one-eight of the specimen height.

6.2 Dry soils

Soils that have less than 5 % fines (passing 75 pim) can be tested dry. if the specimen is prepared in layers, the layer boundary shall not coincide with the shear plane, which may form a weak plane.

NOTE The placement method (dry pluviation, use of tamping or vibration) and density o[the sand are specilied by a suitably experienced and qualified person, such as a geotechnical engineer, requesting the test.

Density or void ratios of dry soil specimens shall be determined as follows:

(a) After the lower plate and grid plate (if used) have been positioned in the base of the box, the dry soil shall be placed to the required density, see below for examples. The mass of soil placed into the box shall be determined by weighing a container plus soil (mi), before pouring and weighing the remaining soil plus container (m2), after pouring. Care shall be taken to recover any soil spilled during this process, and to return it to the container for determination of mz. The mass, m, of soil in the box shall be calculated from Equation 6.1:AS 1289.6.2.2-2020 pdf download.

Methods of testing soils for engineering purposes