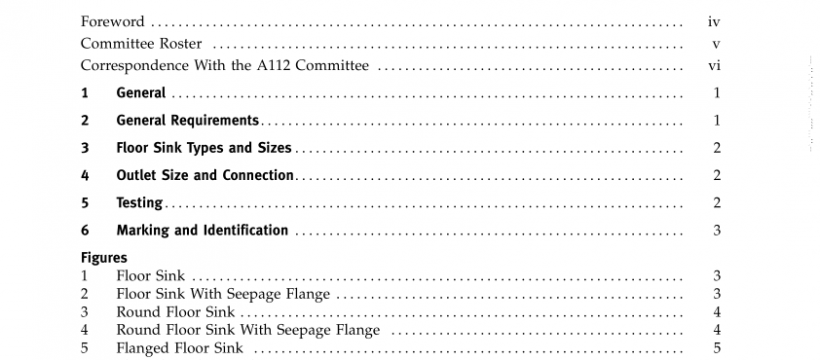

ASME A112.6.7:2010 pdf free download

ASME A112.6.7:2010 pdf free download.SANITARY FLOOR SINKS

3.2 Floor Sinks Without Anchor Flanges

Floor sinks without anchor flanges are for use where anchoring or clamping of a waterproof membrane is not required.

3.3 Floor Sinks With Anchor Flanges

Floor sinks with anchor flanges are for use where anchoring or clamping of a waterproof membrane is required. The membrane is to be secured to the anchor flange with flange clamps. Provisions shall be made in the drain body for weepholes. They shall be cast in the cast iron body and drilled in the PVC body, if necessary (see Figs. 5 through 7).

3.4 Grate Configurations

Grate configurations shall be either full, 3 ⁄ 4 , or 1 ⁄ 2 design. See Figs. 8 through 10. Direction of slots may vary depending on the manufacturer.

4 OUTLET SIZE AND CONNECTION

Outlet size and connections shall be in accordance with ASME A112.6.3-2001 and/or ASTM A 888. PVC shall also be in accordance with ASTM D 2665.

5.3 Acid Test for the Epoxy Coating

The acid test for the epoxy coating shall be a fresh solution made of one part citric acid crystals to ten parts water by weight applied to the surface of the epoxy coating for 15 min, at the end of which period, after washing and drying, there shall be no loss of epoxy. The floor sink and acid solution shall have been stored for not less than 3 hr immediately preceding the test in an atmosphere of 80°F ± 10°F (26.67°C ± 5.55°C). The test shall be applied to a clean area, in a pool ofseveral drops, and covered with a watch glass to hold the solution in place.

6 MARKING AND IDENTIFICATION

Floor sinks shall be marked with the following and shall be visible after installation when the markings are not detrimental to the finish or appearance:

(a) manufacturer’s name or trademark

(b) model number

ASME A112.6.7:2010 pdf free download