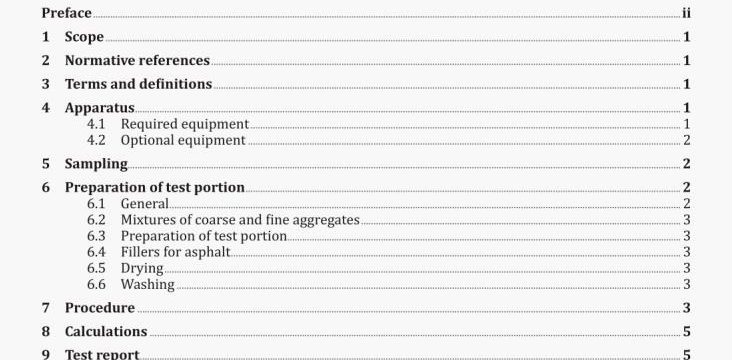

Methods for sampling and testing aggregates

AS 1141-11-1-2020 pdf download.Methods for sampling and testing aggregates

Method 11.1: Particle size distribution — Sieving method.

6.2 Mixtures of coarse and fine aggregates

Mixtures of coarse and fine aggregates shall be separated into two sizes using a 4.75 mm test sieve. The portions obtained shall be measured out and tested separately. The size of the test portion for each fraction shall be in accordance with Table 1.

NOTE The percentage passing each sieve should be calculated on the basis of the total mass of the test portion making appropriate calculations to take into account the ratio of the mass of the fine fraction tested to the total material.

6.3 Preparation of test portion

Test portions may be tested without further preparation or may be washed over a 75 lIm sieve after

drying, see Clause 6.6.

6.4 Fillers for asphalt

Fillers for asphalt shall be separated on a 600 .*m test sieve from material passing a 4.75 mm test sieve.

6.5 Drying

The test portions shall be dried to constant mass. The mass of each fraction or test portion (M1) shall be determined and recorded.

6.6 Washing

With the exception of asphalt fillers (see Clausel Note 2) where an aggregate sample is tested for comparison with a document in which the passing 75 I.lm size is specified, the test portion shall be washed over a 75 m sieve as follows:

(a) Place the dried test portion in a dish or pan and add sufficient clean water to cover it.

NOTE I For materials that contain clay, a dispersing agent that does not react with the test portion may be used.

NOTE 2 The water used should not react with the aggregate.

(b) Vigorously agitate the contents without spilling the water to take the fine material into suspension and immediately pour the wash water through two sieves nested together with a guard sieve. e.g. 1.18 mm sieve, at the top and a 75 m sieve below. Avoid, as far as possible. decantation of the coarse particles of the test portion.

(c) Continue agitation and washing until the water Is clear in the pan. Wash all the remaining test portion over the nested guard sieve and 75 pm sieve using a low-pressure water jet.

(b) Place the test portion in the top sieve.

(c) Agitate the sieves, either by hand or mechanically.

The determination of the time period for operation oleach individual mechanical sieve shaker shall give the same separation as hand sieving.

Material shall not be forced through sieves by hand pressure. On sieves of aperture 19.0 mm and greater, hand-placing of particles, to facilitate passage of particles through the sieve shall be permitted.

When sieving fine materials, such as fillers for asphalt, the underside of the sieves may be lightly brushed with a soft, fine brush to prevent aggregation of particles (balling) and blocking of some of a sieve’s apertures with sample particles (blinding) of the apertures. The following also applies:

(i) Care shall be taken not to apply pressure to the surface of the sieve.

(ii) Brushes with stiff or worn-down bristles shall not be used.

(iii) Alternatively, an air-jet sieve may be used.

Hand sieving shall be completed when no more than an additional 1 % by mass of the residue on any individual sieve passes during a further 1 mm of continuous hand sieving. NOTE I Refer to ISO 2591-1 for a full description of hand sieving.

NOTE 2 In the case of fillers for asphalt or of other similarly fine materials, the sample should not be washed, since washing usually causes balling of the finest fractions and consequent blinding of the sieve apertures. In addition, some fillers either react with or are partially dissolved by water.

Fillers may be sieved over the fine sieves, including the 75 im sieve, using an air-jet sieve apparatus.

(d) Determine the mass of material retained on each sieve and ensure that this mass does not exceed that specified in Table 2.

NOTE 3 In production testing of aggregates. if the amount of material likely to be retained on any one sieve does not exceed the amount specified in Table 2, cumulative measuring ol the material retained may be performed.

(e) If the mass of material retained on any one sieve exceeds the permissible mass for that sieve, as shown in Table 2, divide the material retained on the sieve concerned into sub-portions, none of which shall exceed the permissible mass shown in Table 2. Retest as follows:

(i) Re-sieve each sub-portion for not less than 2 mm.AS 1141-11-1-2020 pdf download.

Methods for sampling and testing aggregates