AS NZS 4389:2015 pdf free download

AS NZS 4389:2015 pdf free download.Roof safety mesh

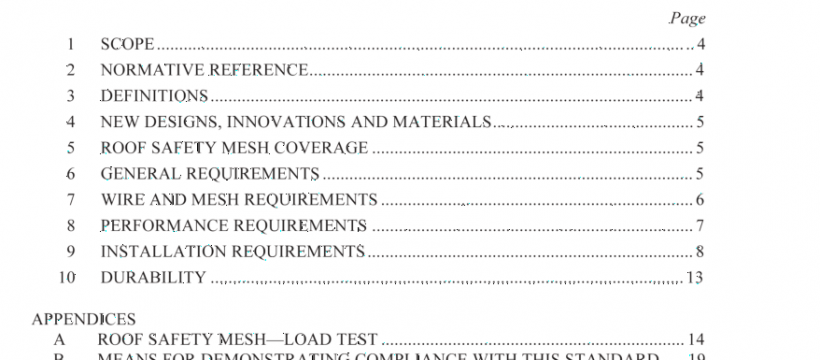

9.3 Fixing of roof safety mesh

All longitudinal wires of roof safety mesh shall be fixed to the roof members in one of the following ways, as applicable to the construction of the roof members:

(a) Steel construction Where the roof members are of metal construction,the longitudinal wires, including lapped wires, of the roof safety mesh shall be attached in one of the following methods:

(i) The wires shall be passed through a hole drilled at a spacing of 150士5 mm in the top of the purlin and tied off with at least four full turns around the same wire, as shown in Figure 1(a).

(ii) The wires shall be passed once completely around the roof member, the tail of every wire being twisted four times around the main portion of the same wire, as shown in Figure 1(b).

(iii) The wires shall be attached to predrilled supporting member where all longitudinal wires (including lapped wires) shall be passed through the predrilled holes in the projecting half of the metal strip with the tail wire being twisted 4 times around the main portion of the wire as shown in Figure 1(d). Attachment of the supporting member to the roof structure shall be in accordance with manufacturer’s installation specification.

(b) Timber construction Where the roof members are of timber, the longitudinal wires of the roof safety mesh shall be attached using either one of the follow ing methods:

(i) The wires shall be bent over and down, and fixed to the sides of the purlins by means of galvanized steel staples of not less than the gauges, lengths and spacing specified in Table 2, as shown in Figure l(c). .

(ii) The wires shall be fixed to the tops of the roof members by means of galvanized steel staples of not less than the gauges, lengths and spacing given in Table 2. All staples shall be driven in such manner that a transverse wire is between the end of the wire and the staple, or the end of the wire is bent back and twisted four times around the same wire so that individual wires cannot be drawn from a staple, as shown in Figure 1(c).

(c) Fixing of the longitudinal wires when the method in Item (a) or (b) is not possible Longitudinal wires shall be secured to the roof member by means of galvanized steel wire loops of not less than 3.15 mm diameter by placing the centre of the tying wire around the longitudinal wire at a point of intersection of a transverse wire, so that a transverse wire is between that point and the end of the longitudinal wire, and next passing both ends of the tying wire once completely around the roof members, and then drawing the two tails of the tying wire in opposite directions over the two strands of the tying wire and twisting together with at least three complete turns, as shown in Figure 1(e).

AS NZS 4389:2015 pdf free download