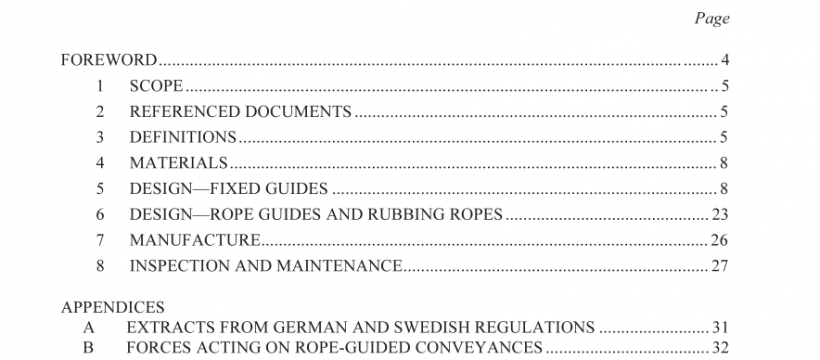

AS NZS 3785.6:2015 pdf free download

AS NZS 3785.6:2015 pdf free download.Underground mining—Shaft equipment

5.9.9 Guide stiffness

The following recommendations apply to the stiffness of fixed guide connections:

(a) Guide splices should be designed to minimize the change in the guide bending stiffness in any direction along the length of a guide.

(b) The design of the guide supporting system (buntons and dividers) and guide supports should be such that the change in horizontal stiffness in any direction as the guide passes over a support point is minimized.

6.1 General

The function of rope guides is to control the motion of the conveyances so as to prevent conveyances from colliding with one another or with the shaft walls and fixtures during hoisting.

Historically, rubbing ropes have sometimes been installed between conveyances with the objective of preventing a collision between conveyances or minimizing the magnitude of a collision in the event that the rope guides did not prevent a collision. Rubbing ropes are rarely used in modern practice.

Rope guides are not stiff enough to provide adequate restraint of conveyances during conveyance loading and unloading. Short lengths of conventional fixed steel guides should be provided for this purpose. Provisions for the design of fixed guides in conveyance loading and unloading locations can be found in Clause 5.4.5.

Historically, empirical data collected over time from practical experience has been used to design rope guidance systems using static clearances only. Mining regulations of several countries specify minimum requirements and the static clearances between conveyances and shaft walls.

NOTE: Some examples taken from German and Swedish regulations are shown in Appendix A. These guidelines may be suitable for some applications; however, they shall not be adopted without—

(a) assessment of the dynamic clearances; or

(b) rigorous evaluation of the proposed design against existing successful designs.

For Item (a), the dynamic clearances are specified in Clauses 6.2.2 and 6.2.3.

For Item (b), the existing design shall meet the clearances specified in Clause 6.2.2. Factors for the evaluation should include the following:

(i) Depth of shaft.

(ii) Hoisting speed.

(iii) Ventilation air velocity and direction.

AS NZS 3785.6:2015 pdf free download