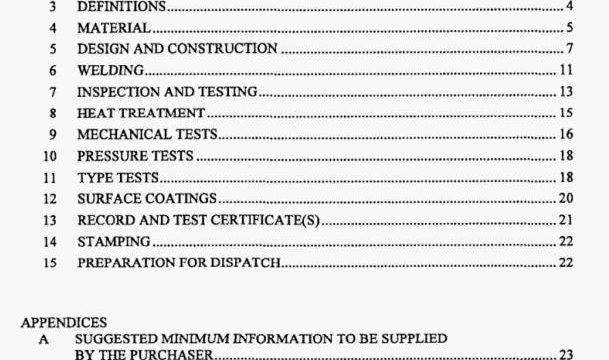

AS 2470-2005 pdf download.Steel cylinders for compressed gases— Welded three-piece construction with longitudinal joint-11 kg to 150 kg.

4.2.1.4 Mechanical properties

When a completed gas cylinder is tested in accordance with Clause 9.3, the yield and tensile strength values obtained shall be not less than the values used in the equations in Clause 51.1.

When determined in accordance with Clause 9.3, the elongation shall be not less than 20%

minus one percentage unit for each increment of 50 MPa by which the measured tensile

strength exceeds 350 MPa, but in any case not less than 16%.

4.2.2 Attachments

Attachments shall be of steel complying with the requirements of Clause 4.1, except that for resistance-welded attachments the steel of both components of the joint shall be weldable and be subject to a maximum carbon content of 0.15%.

4.3 Stainless steel

4.3.1 Cylindrical section and ends

4.3.1.1 Cast analysis

The cast analysis shall comply with the chemical composition requirements of grades 304/304 L or 316t316 L as specified in ASTM A240/A240M and ASTM A4*0/A4SOM, except that the maximum carbon content shall not exceed 0.05%.

4.3.1.2 Test ccrtiJkates

Test certificates shall be provided by the stainless steel supplier, with each completed order to indicate the material and mechanical properties of the stainless steel supplied.

For temper rolled stainless steel, tensile specimens shall be taken from both ends of each coil. For test certificate purposes, all specimens shall be taken at a sufficient distance from coil ends in order to be fully representative of the coil.

4.3.1.3 Mechanical properties

All tests specified in Section 9 are required. When a completed cylinder is tested in accordance with Clause 9.3 of this Standard, the yield and tensile strength values obtained shall not be less than those values used in the equations in Clause 5.1.1 of this Standard.

When determined in accordance with Clause 9.3 of this Standard, the elongation shall be not less than 20% minus one percentage unit for each increment of 50 MPa by which the measured tensile strength exceeds 350 MPa, but in any case not less than 16%.

4.3.1.4 lntergranular corrosion tests

These intergranular corrosion tests shall comply with the requirements of AS 203g. For welded variables, materials and welding procedures shall be qualified by testing a specimen from a least one cylinder randomly selected from each batch of 200 cylinders or part batch thereof.

5.2 Form of ends

Ends shall be concave to pressure, and shall have either spheric.] form or ellipsoidal form

(see Figure 1).

The ends shall have a cylindrical portion of length not less than four times the minimum

thickness.

Ihe ellipsoidal tórm shall be of not more than 2 to I ratio at the internal surface, I.e. the internal height of the end is 25% of the internal diameter. A template of true form shall be used internally or externally to check the deviation from the true form. Any deviation measured perpendicular to the surface shall not exceed 1.25% of the nominal external diameter of the cylinder (see Figure 1).

5.3 Footrlng

A cylinder intended to be freestanding and upright in service shall be fitted with a footring which shall be clear of, and in such a position that it will not obstruct the inspection of any circumferential joint. The footring shall not entrap liquid when the cylinder is in the standing position, and the space enclosed by the footring shall be suitably ventilated.

A cylinder of water capacity, greater than 27 kg and not greater than 150 kg, shall have any edge of the footing on which the cylinder is intended to stand curled in, to reduce the likelihood of injury to feet and hands.

NOTE: Clause 5.6.4 gives requirements for footring attachments.

5.4 Length to outside diameter ratio

Thc ratio of lcngth over the cads to the outside diameter of the cylinder shall be not greater than 4.0 to 1, except where calculation or test shows to the satisfaction of a competent person that a greater ratio is suitable.

5.5 Valve protection

Where required by AS 2030.1, valve protection shall be provided in accordance with

AS 2030.1. Valve protection shall be capable of withstanding the strength test specified in

Clause 11.5.

5.6 Pressure-retaining joints

5.6.1 General

There shall be one longitudinal joint and two circumferential joints. The main longitudinal joint and circumferential joints shall be of a quality not inferior to that produced by electric arc wclding by a machine process using automatic feed and welding guidance mechanism. Other equivalent automatic processes, with the exception of resistance welding. may be used.AS 2470-2005 pdf download.Steel cylinders for compressed gases

Steel cylinders for compressed gases