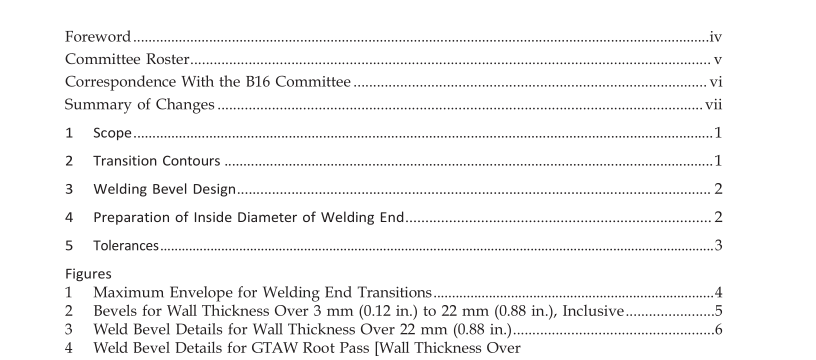

ASME B16.25:2012 pdf free download

ASME B16.25:2012 pdf free download.Buttwelding Ends

3.3 Outside Diameter at Welding Ends

Dimension A shall be either that specified in the applicable component standard or that specified in the purchaser’s component specification. In the absence of a requirement for dimension A in a component stan- dard or a purchaser’s specification, the values for dimen- sion A in Table 1 or Table I-1 may be used.

4 PREPARATION OF INSIDE DIAMETER OF WELDING END

4.1 General

Preparation of the inside diameter at the end of a component shall be in accordance with one of the follow- ing, as specified by the purchaser:

(a) Components to be welded without backing rings shall meet the requirements of the standard or specifica- tion for the component.

(b) Components to be welded using split or noncon- tinuous backing rings shall be contoured with a cylindri- cal surface at the end as shown in Fig. 2, illustration (b) and Fig. 3, illustration (b). If the backing ring contour is other than rectangular, details must be furnished by the purchaser.

(c) Components to be welded using solid or continu- ous backing rings shall be contoured with a cylindrical or tapered surface at the end as specified by the pur- chaser. End preparation is illustrated in Fig. 2, illustra- tion (c) and Fig. 3, illustration (c) for rectangular ends and in Fig. 2, illustration (d) and Fig. 3, illustration (d) for tapered ends.

(d) Components to be welded using consumable insert rings or GTAW root pass shall be contoured with a cylindrical surface at the end as shown in Figs. 4 through 6.

4.3 Exceptions

(a) For pipe or tubing varying from the ASTM A106 and A335 types, having different wall thickness and/or outside diameter tolerances (such as forged and bored pipe), the foregoing equations may be inapplicable. Equations (1) and (2) may be used to determine C for these applications. The purchaser shall specify the C dimension when Tables 1 and I-1 data do not apply.

(b) For components in smaller sizes and lower sched- ule numbers, it may be necessary to deposit weld metal on the inside diameter (I.D.) or use thicker wall materials in order to machine the backing ring while maintaining required wall thickness. This condition may also arise when using material whose nominal dimensions indi- cate sufficient metal but whose actual I.D., considering tolerances, is large enough to require additional metal.

ASME B16.25:2012 pdf free download