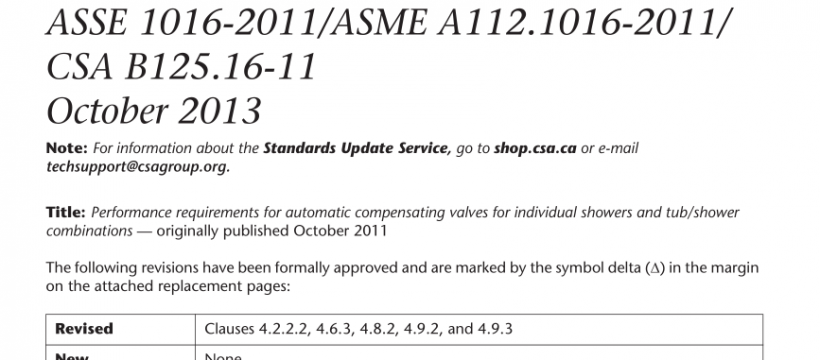

ASME A112.1016:2011 pdf free download

ASME A112.1016:2011 pdf free download.Performance requirements for automatic compensating valves for individual showers and tub/shower combinations

4.6.1 Purpose

The purpose of this test is to determine if the outlet water temperature at the point-of-use is maintained within a set temperature range.

4.6.2 Data gathering, all types of devices (see Figure 1)

Data shall be gathered as follows:

(a) The temperature-recording device shall be started 1 0 s before the step changes.

(b) Temperature measurements shall be taken at temperature sensors T1 , T2, and T3 with measuring equipment capable of detecting a 63.2% step change within 0.3 s with a frequency rate of 20 Hz (one value every 0.05 s) for 25 ± 5 s unless otherwise specified in this Standard. See Annex A.

(c) The outlet temperature measurements at sensor T3 shall be averaged every 0.25 s.

(d) Temperature sensors T1 , T2, and T3 shall be located as follows:

(i) Temperature sensors T1 , T2, and T3, within the flow stream in Type K or Type L copper water tube.

(ii) Temperature sensors T1 and T2, within 91 4 mm (36 in) of the device.

(iii) Temperature sensor T3, within 91 4 ± 1 3 mm (36 ± 0.5 in) from the outlet of the device. The

outlet tube shall be the same size as the outlet connection size of the device.

Notes:

(1) For verifying the time constant of the temperature-measuring equipment, see Annex A.

(2) Data can be gathered in formats similar to those depicted in Figures B.1 to B.5.

4.6.3 Procedure — All types of devices (see Figure 1)

Controllers with pressure feedback loops shall not be active during the tests, but may be used to set the test parameters.

Note: Controllers with pressure feedback loops interact with the specimen and result in inaccurate test results. The pressure and temperature variation test shall be conducted as follows:

(a) Set up the specimen as shown in Figure 1 , with valves V1 , V2, and V3 and the device’s valve in the fully open position.

(b) Adjust and maintain the hot and cold water supply pressures directly upstream of the inlet connections to a flowing pressure of 31 0.3 ± 1 3.8 kPa (45.0 ± 2.0 psi), as measured by gauges G1 and G2.

(c) Adjust the temperatures at temperature sensors T1 and T2 so that there is a temperature differential of 44.0 to 56.0 °C (80.0 to 1 00.0°F) between the hot water temperature [minimum of 60.0 °C (1 40.0°F)] and the cold water temperature [maximum of 21 .1 °C (70.0°F)]. After the hot water and cold water inlet temperatures are established maintain the inlet temperatures at ±1 .0 °C (±2.0°F).

(d) Adjust the device so that the outlet temperature at temperature sensor T3 (point of use outlet) is 40.5 ± 0.5 °C (1 05.0 ± 1 .0°F).

ASME A112.1016:2011 pdf free download