Destructive tests on welds in metallic materials

AS NZS 2205.3.1-2020 pdf download.Destructive tests on welds in metallic materials

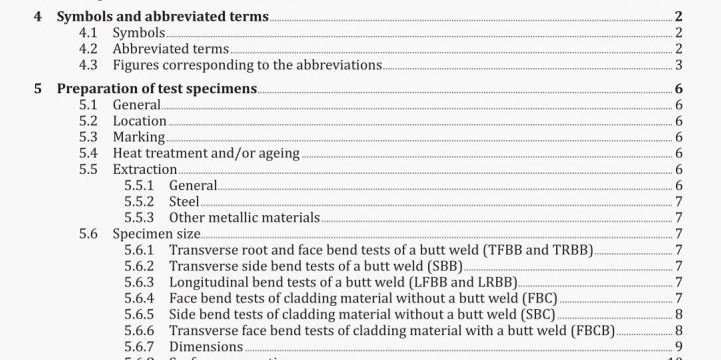

Method 3.14 Bend tests.

5.5.3 Other metallic materials

Sheared or thermal cut surfaces are not permitted on bend specimens; only machining (e.g. sawing, grinding or milling) shall be used.

5.6 Specimen size

5.6.1 Transverse root and face bend tests of a butt weld (TFBB and TRI3B) See Figures 1,2 and 9.

For transverse root and face bend tests, the test specimen thickness, t, shall be equal to the thickness of the base material adjacent to the welded joint up to a maximum thickness of 30 mm. If the test piece thickness, t, is greater than 10 mm, the test specimen thickness, t5, may be machined or otherwise mechanically finished from one side to a thickness equal to (10 ± 0,5) mm as indicated in Figures 1 and 2. The face or root of the weld shall be in tension when the specimen is bent.

When a relevant application standard requires testing of a full thickness > 10 mm, several test specimens may be taken in order to cover the full thickness of the joint as indicated in Figure 9.

In such cases, the location of the test specimen in the welded joint thickness shall be identified.

5.6.2 Transverse side bend tests of a butt weld (SBB) See Eigut and 10.

For side bend tests, the test specimen width. b, shall be equal to the thickness of the base material of the welded joint. The specimen shall have a thickness, t5, of at least (10 ± 0,5) mm, unless otherwise specified in the relevant application standard.

When the joint thickness exceeds 40 mm, it is permissible to split the specimen in the plane of the test piece thickness as shown in FigureJQ. In these cases the location of the test specimen in the welded joint thickness shall be identified.

5.6.3 Longitudinal bend tests of a butt weld (LFBB and LRBB) See Figure 4.

For longitudinal bend tests, the test specinwn thickness, t. shall be equal to the thickness of the base material near the welded joint, but should not exceed 10 mm. If the test piece thickness, t, is greater than 10 mm, the test specimen thickness, t5, may be machined or otherwise mechanically finished from one side to a thickness equal to (10 ± 0,5) mm as indicated in Figure 4. The face or root of the weld shall be in tension when the specimen is bent.

For face bend tests, the test specimen thickness, ts, shall be equal to the thickness of the base material plus the thickness of the cladding, but should not exceed 10 mm. If the test piece thickness, t, is greater than 10 mm, the test specimen thickness, t, may be machined or otherwise mechanically finished from the base metal to a thickness equal to (10 ± 0,5) mm as indicated in Figure 5, if cladding thickness permits.

When the thickness of the base material plus cladding is greater than t5, it is permissible to remove base material In order to produce a test specimen thickness, t, in accordance with the application standard or as agreed between the contracting parties.

5.6.5 SIde bend tests of cladding material without a butt weld (SBC) See Figure 6.

For side bend tests, the test specimen width. b, shall be equal to the thickness of the base material plus the thickness of the cladding, up to a maximum of 40 mm. The specimen shall have a thickness, t, of at least (10 ± 0,5) mm, unless otherwise specified in the relevant application standard.

When the thickness of the base material plus cladding exceeds 40 mm, it is permissible to remove base material to produce a test specimen width, b, in accordance with the relevant application standard or as agreed between the contracting parties.

5.6.6 Transverse face bend tests of cladding material with a butt weld (FBCB) See Figure 7.

For transverse face bend tests of cladding with a butt weld, the test specimen thickness, t, shall be equal to the thickness of the base material plus the thickness of the cladding, but should not exceed 10 mm. lithe test piece thickness, t, Is greater than 10 mm, the test specimen thickness, t, may be equal to (10 ± 0,5) mm, if cladding thickness permits.

In such a case, the location of the weld shall remain in the middle of the test specimen or at a suitable position for testing.

When the test concerns the complete joint incorporating both the butt joint and the cladding and when the thickness of the joint Is greater than t, several specimens may be taken as described in 5.6.1 and Figure 9.

When the purpose of the test is to examine the cladding only and when the thickness of the base material plus cladding is greater than t, no further tests on the base material are required.AS NZS 2205.3.1-2020 pdf download.

Destructive tests on welds in metallic materials