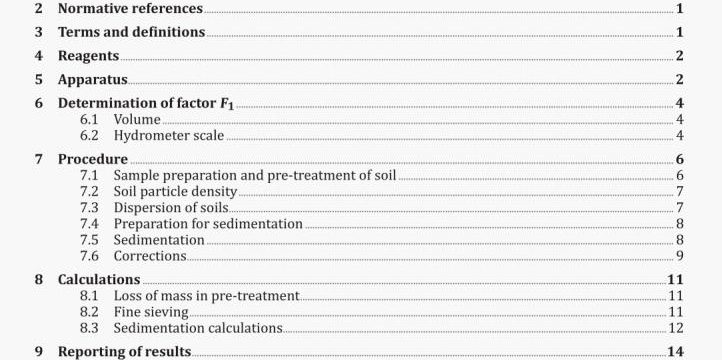

AS 1289.3.6.3-2020 pdf download.Methods of testing soils for engineering purposes

Part 3.6.3: Soil classification tests— Determination of the particle size distribution of a soil — Standard method of fine analysis using a hydrometer.

7.4 Preparation for sedimentation The procedure shall be as follows:

(a) Transfer the liquid to the stirring device cup and operate for 15 mm. lithe volume of liquid exceeds the capacity of the cup, this process will need to be completed in multiple steps as follows:

(i) Transfer the mixture to the high-speed mechanical stirrer or to the air-jet dispersion cup, using a jet of distilled water.

(ii) Transfer the suspension that has passed through the sieve to the I L measuring cylinder and make up to exactly 1 L with distilled water. This makes the suspension to be used in the sedimentation analysis.

For soils likely to suffer severe structural breakdown, it is recommended that the air dispersion device be used, and mechanical dispersion not be used before washing over the 75 pm sieve.

(c) In the case of (a) or (b) operate the dispersion device for 15 mm. When using the mechanical stirrer use the baffle in the mechanical stirrer container. When using the air-jet dispersion device, operate it at a gauge pressure of 140 kPa ± 10 kPa.

7.5 Sedimentation

The procedure shall be as follows:

(a) Place the 1 L cylinder containing the suspension in the constant temperature room, or bath and preferably leave it to stand until it has attained the ambient temperature of 20 UC ± I °C. Close the mouth of the cylinder with the palm of the hand, or with a suitable watertight stopper or lid, and turn the cylinder end over end thoroughly for about 60 rotations in 1 mm.

Immediately after shaking, place the cylinder on a firm, level and vibration-free place in the constant temperature room or bath. Then proceed as follows:

(i) Start the stop-clock and record the time of commencement of the test.

(ii) Immediately immerse the hydrometer to a depth slightly below its floating position and allow it to float freely.

(iii) Take readings at the top of the meniscus at 0.5-. 1-, 2-, and 4-mm intervals and record readings to the nearest gram per litre (or 0.0005 g/mL) (Rh).

(iv) Remove the hydrometer slowly, rinse it in distilled water, and place it in another cylinderoldistilled water, which is at the same temperature as thatof the suspension.

(d) At the conclusion of the sedimentation test —

(I) transfer the contents of the cylinder after decantation to an evaporating dish (mass determined to within 0.01 g);

(ii) dry in the oven at 105 °C to 110 °C;

(iii) cool in the desiccator and determine the mass ofthe contents to the nearest 0.01 g; and

(iv) record the mass as the mass of the fraction passing the 75 pm sieve (m6u) uncorrected for dispersing agent.

(e) For soils which do not require pre-treatment, or where the mass of material in suspension at the commencement of the hydrometer analysis has been found in the course of its preparation during fine sieve analysis (refer to AS 1289.3.6.1), omit the drying of the material after hydrometer analysis.

For soils which did require pre-treatment, obtain the mass of the fraction passing the 75 pm sieve (m6) from the difference between the calculated oven-dry mass (m4) of the subsample obtained in Clause 7.1(a) and the oven-dry mass (ms) of the fraction of the sample retained on the 75 pm sieve.

7.6 Corrections

Corrections to the readings shall be made as follows:

(a) Correction for dispersing agent in the fraction passing 75 pm sieve:

(I) Place 100 mL of the dispersing agent solution in an evaporating dish of known mass and dryat 105 °Cto 110°C.

(ii) Determine the mass of the contents to the nearest 0.01 g (md).

(iii) Deduct this mass from the mass (m6u) and record the result as m6, the correct mass of the fraction passing the 75 pm sieve, i.e. m6 = — md.

(b) Dispersing agent correction to hydrometer readings (see Clause 10 Note 8):

(I) Place 100 mL of the dispersing agent solution into a 1 000 mL graduated cylinder, make up to 1 000 mL with distilled water and place the cylinder in the constant temperature room or bath, maintained at 20 °C ± 0.5 °C.

(ii) When the solution has attained equilibrium temperature, insert the hydrometer and take a reading. For hydrometers calibrated in grams per litre.AS 1289.3.6.3-2020 pdf download.Methods of testing soils for engineering purposes

Methods of testing soils for engineering purposes