AS 1012.25.1-2020 pdf download.Methods of testing concrete

Method 25.1: Determination of the fibre content of plastic state concrete (wash-out test).

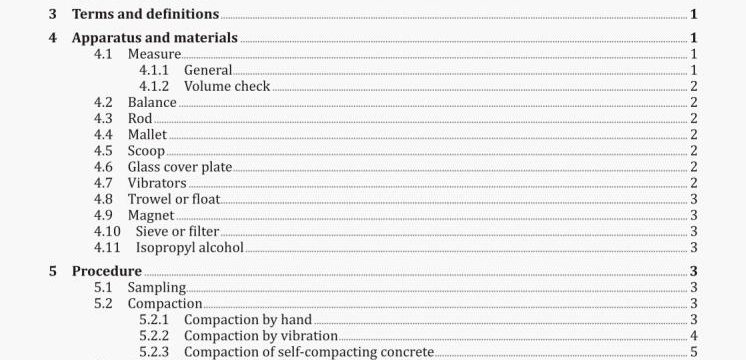

4.11 Isopropyl alcohol

Technical grade Isopropyl alcohol for use where synthetic fibres are being used.

5 Procedure

5.1 Sampling

(a) For concrete sampled in the field, the test sample shall be obtained in accordance with the requirements of AS 1012.1. Commence the test immediately following the completion of mixing the test sample. For concrete prepared in the laboratory, the test sample shall be prepared in accordance with AS 1012.2.

NOTE Due to the nature of the testing procedure, concrete sampled in the field may need to be tested away from the sampling site. In this situation, a set retarding agent may be added to the sample to enable testing at an alternative location.

(b) Place and fully compact the concrete in the measure by one of the methods described in Clause 5.2 without causing segregation or excessive laitance. No slump concrete shall be compacted only by the vibration method. The concrete shall be levelled off with a trowel or float to be flush with the top of the container.

5.2 Compaction

5.2.1 Compaction by hand

Compaction shall be carried out as follows:

(a) Fill the measure in three approximately equal layers with the scoop. As each scoopful of concrete is being placed into the measure, move the scoop around the top edge of the measure as the concrete slides out, to ensure symmetrical distribution of the concrete within the measure.

(b) Fully compact each layer by rodding. Rod the bottom layer throughout its depth. For each upper layer, penetrate Into the underlying layer with at least the first 10 strokes.

NOTE 1 The minimum number of strokes per layer required to compact average concretes with different consistencies is set out as a guide for up to 250 mm diameter measures in Table 1. For slumps of less than 40 mm, refer to AS 1012.8.1.

NOTE 2 More strokes are required for bowls of larger diameters, proportional to the area.

Where the concrete contains weak lightweight aggregate particles that degrade with hand compaction, a reduced number of tamping blows and increased tapping of the measure may be adopted, provided that the complete compaction is achieved.

(c) After each layer is rodded, tap the side of the measure 10 to 15 times with the mallet to release any air bubbles and to close any surface voids.

(d) Place sufficient concrete in the last layer to slightly overfill the measure when compacted. However, where the measure is not completely filled after compaction of the top layer, some additional concrete may be added and worked into the surface with a trowel or float.

(e) Strike off the surface of the concrete and smoothly finish with the glass cover plate to ensure the measure is volumetrically filled.

5.2.2 Compaction by vibration

Compaction by vibration shall be carried out as follows:

(a) Fill the measure in two approximately equal layers with the scoop. As each scoopful of concrete is being placed into the measure, move the scoop around the top edge of the measure as the concrete slides out, to ensure symmetrical distribution of the concrete within the measure.

(b) Place all the concrete for each layer before commencing vibration.

(c) Vibrate each layer only long enough to achieve full compaction. Avoid over-vibration.

NOTE The duration of vibration required to compact each layer will depend upon the workability of the concrete and the effectiveness of the vibrator. Usually the surface of the concrete becomes relatively smooth in appearance and substantial air bubbles cease breaking the surface when sufficient vibration has been applied, Extreme care should be taken to avoid segregation when using vibration to compact concrete with slump greater than 100 mm.

(d) Where an internal vibrator is used, compact each layer by four insertions of the vibrator at points symmetrically distributed over the cross-section of the measure. Do not allow the vibrator to rest on the bottom of the measure or touch the sides of the measure. Take care to withdraw the vibrator in such a manner that no air pockets are left in the specimen. After vibrating the top layer, tap the sides of the measure sharply 10 to 15 times with the mallet.

(e) Where external vibration is used, rigidly attach or securely hold the measure against the vibrating element or vibrating surface.

(f) Add the top layer so as to avoid overfilling of the measure by more than 6 mm and thus losing excessive mortar by overflowing during vibration. After vibrating the top layer, some additional concrete may be added and worked into the surface with a trowel or float.AS 1012.25.1-2020 pdf download.Methods of testing concrete

Methods of testing concrete