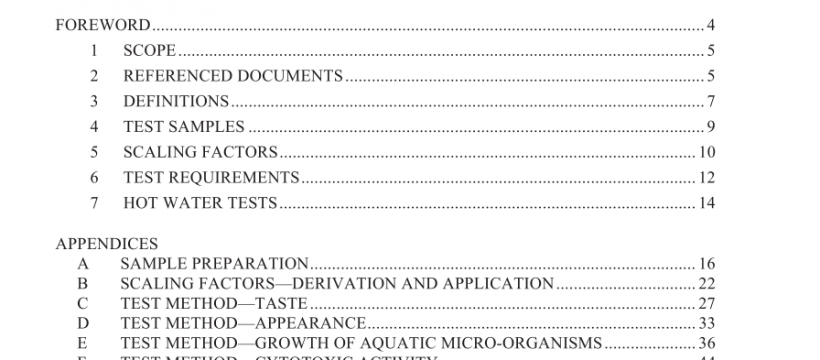

AS NZS 4020:2018 pdf free download

AS NZS 4020:2018 pdf free download.Testing of products for use in contact with drinking water

4.2 Range of product sizes

Where a manufacturer produces a complete range of product sizes of the same material composition, tests on the greatest surface area-to-volume ratio product shall qualify the remainder of the range, provided that the same manufacturing conditions and processes are used for the complete range of products.

4.3 Product exposure

Wherever possible, samples of the product shall be tested by in-the-product exposure (see Paragraph A4.1), so that only the surface that is normally wetted in end use is exposed to the test water.

Where in-the-product exposure is not possible, or where unfabricated material is being tested, the product surface or a representative sample of the material surface shall be tested by immersion exposure (see Paragraph A4.2). The ratio of exposed surface area to test water volume for immersion exposure testing shall be equal to (within 5%) or greater than the surface area-to-volume ratio in the intended end use, and shall not be less than 1000 mm2/L. Where testing for the growth of aquatic micro-organisms, the ratio shall be in the range 1000 mm2/L to 15 000 mm2/L.

Where the end-use exposure is greater than 15 000 mm2/L, the test result shall be based on a testing exposure of 15 000 mm2/L and no scaling factor shall be applied to this result. Where a product has multiple non-metallic components, the non-metallic wetted components shall be tested at the end-use exposure, with the exception that end-of-line fittings shall be tested at an exposure for each component in contact with 250 mL of water. The MDOD result shall be the average of the results for individual components.

An exception applies in certain cases of in-the-product testing, where in end use the internal surface of the product is effectively in contact with a substantially larger volume of water than in the test. Examples of such products are valves and fittings connected into water supply pipelines. A further exception applies in the testing of end-of-line-fittings such as taps and their components, where in the end-use situation the extract contained in the fitting is effectively diluted before consumption. Similarly, the use of a composite extract in the metals extraction test for end-of-line fittings has the effect of providing an inbuilt scaling factor.

AS NZS 4020:2018 pdf free download