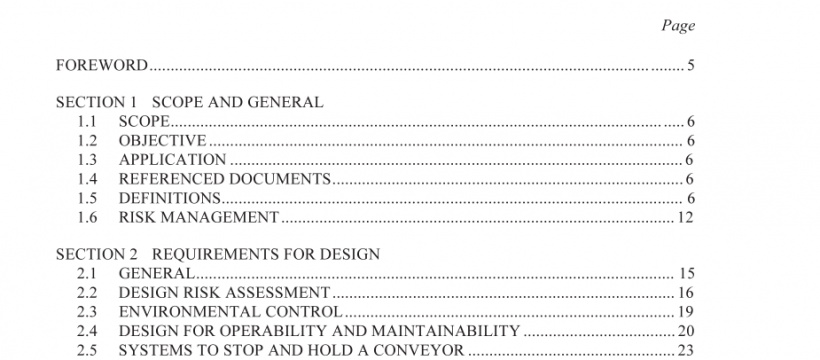

AS NZS 4024.3610 2015 pdf free download

AS NZS 4024.3610 2015 pdf free download.Safety of machinery

2.10.5.3 Components and elements to achieve the emergency stop function

Where a conveyor needs to be fitted with components and elements to achieve an emergency stop function to enable actual or impending emergency situations to be averted or mitigated, the following requirements apply:

(a) The actuators shall be clearly identifiable, clearly visible and readily accessible.

(b) The hazardous process shall be stopped as quickly as possible without creating additional hazards. If this is not possible or the risk cannot be reduced, it should be questioned whether implementation of an emergency stop function is the best solution.

Once active operation of the emergency stop device has ceased following an emergency stop command, the effect of this command shall be sustained until it is reset. This reset shall be possible only at that location where the emergency stop command has been initiated. The reset of the device shall not by itself cause a restart command, except for conveyors at mines, where a pre-start warning compliant to Clause 2.10.4 is installed.

NOTE: More details for the design and selection of electrical components and elements to achieve the emergency stop function are provided in AS 60204.1.

2.10.5.4 Person-on-conveyor stop

The design risk assessment should consider—

(a) the potential for a person to inadvertently be on a moving conveyor;

(b) the severity of injury to a person in the event they are on the conveyor; and

(c) whether a risk control measure is required.

NOTE: For example, on belt conveyors, an emergency stop system should be considered, and it should be located no closer to the conveyor discharge or other hazard than the maximum stopping distance of the conveyor. Consideration should be given to the emergency stop system being accessible for a person inadvertently on the conveyor.

AS NZS 4024.3610:2015 pdf free download