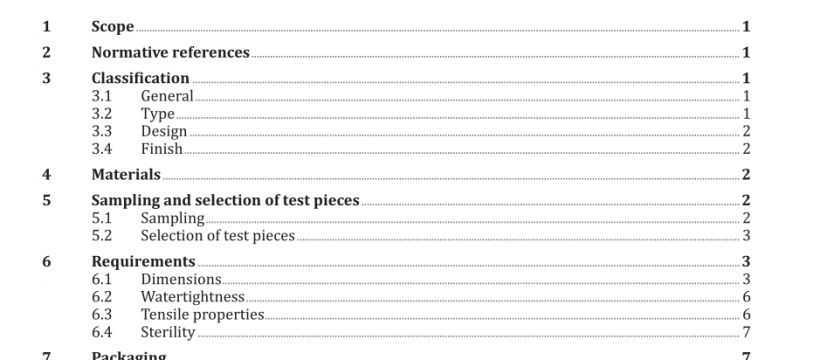

AS NZS 4179:2014 pdf free download

AS NZS 4179:2014 pdf free download.Single-use sterile rubber surgical gloves—Specification (ISO 10282:2014, MOD)

6.3.1 General

Tensile properties shall be measured using a tensile tester in accordance with ISO 5893, Class 1 .0 or better. The speed of the testing machine shall be 500 mm/min ± 1 0 mm/min. Dumb-bell test pieces shall be cut using a Type 2 dumb- bell cutter as specified in ISO 37, taking three test pieces from each glove and using the median value as the test result for each individual glove tested. Test pieces shall be taken from the palm or back of the finished, sterile gloves, with the long axis parallel to the fingers.

6.3.2 Protection of samples and test pieces

Samples and test pieces shall be protected as completely as possible from light and heat prior to testing.

6.3.3 Conditioning of samples

Condition all samples, at a standard laboratory temperature, without humidity control, for not less than 3 h prior to cutting out the test pieces.

6.3.4 Force at break and elongation at break before accelerated ageing

When determined in accordance with 6.3.1 to 6.3.3, the tensile properties shall be as specified in Table 3.

NOTE The requirements of Clauses 6.3.1 to 6.3.4 are intended to mirror those of ISO 37, as far as is possible, in view of the type of test piece available.

6.3.5 Force at break and elongation at break after accelerated ageing

Accelerated ageing tests shall be conducted in accordance with the method specified in ISO 1 88. After the test pieces cut from the gloves have been subjected to a temperature of 70°C ± 2°C for 1 68 h ±2 h, the value of the force at break and the elongation at break shall comply with the requirements given in Table 3, using the inspection level and AQL given in Table 1 .

6.3.6 Force required to produce 300% elongation

When determined in accordance with the method specified in Clauses 6.3.1 to 6.3.3, using type 2 dumb-bell test pieces, the force required to produce an elongation of 300% shall comply with the requirements given in Table 3, using the inspection level and AQL given in Table 1 .

6.3.7 Glove cuff rupture resistance

Glove cuff rupture testing is not mandatory, but might be needed when the cuff rupture resistance of a particular product is in dispute. A test method for glove cuff rupture resistance is set out in Appendix ZA. The force required to rupture the material of the cuff of the glove should not be less than 5 N.

AS NZS 4179:2014 pdf free download