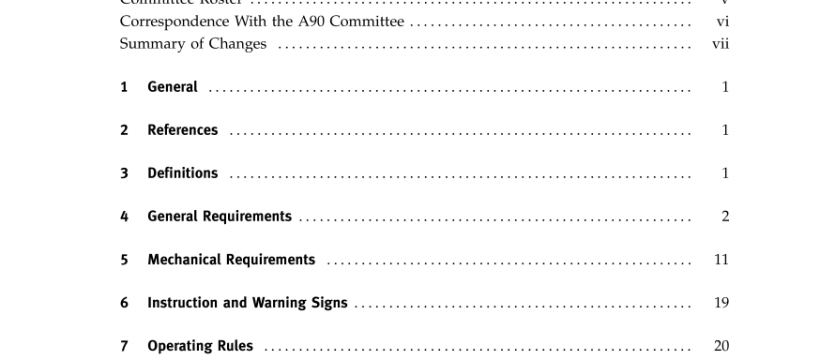

ASME A90.1:2015 pdf free download

ASME A90.1:2015 pdf free download.Safety Standard for Belt Manlifts

5.1.1 Types. Machines shall be the direct-connected type. Cast-iron gears shall not be used. There shall be no 90-deg shoulders machined onto any shaft in manlift machines or pulleys. NOTE: Existing multiple V-belt drive systems are permissible. All new installations shall be the direct-connected type. When one V-belt is replaced, all belts shall be replaced.

5.1.2 Brake

(a) Amechanicallyapplied,electricallyreleasedbrake shall be provided. The brake shall be capable ofstopping and holding the manlift when the down-side is loaded with 200 lb (90 kg) on each step.

(b) All new belt manlifts and complete drive assem- blies shall be equipped with a mechanically applied, manually released brake that will prevent free-wheeling of the head pulley and/or head pulley shaft due to couple, shafting, or reducer failure. This brake, when applied, shall cut off the power to the manlift motor and prevent rotation of the head pulley and/or head pulley shaft.

5.2.1 Material. The material shall be laminated belt- ing, solid-woven PVC belting, or other types of belting meeting the strength requirements of para. 5.2.3. It shall have a coefficient of friction such that when used in conjunctionwithanadequatetensiondevice,itwillmeet the brake test specified in para. 5.1.2.

5.2.2 Width. Belts shall meet Rubber Manufacturers Association (RMA) tolerances for width. The minimum tolerances shall be as follows (see Table 2):

(a) New Installations. The width of the belt shall be not less than 14 in. (355 mm) for a travel not exceeding 150 ft (46 m), and 16 in. (405 mm) for a travel exceeding 150 ft (46 m) for new manlift installations.

(b) Existing Installations. The width of the belt may be less than those dimensions specified in para. 5.2.2(a), but never less than 12 in. (305 mm) nor less than that of the original belt. If a belt of at least 12 in. (305 mm) in width is to be used for a travel that exceeds 100 ft (30 m), the total tensile strength of the belt (its tensile strength rating per inch of width multiplied by its width) must meet the total tensile strength of the belt as called for by the strength requirements and safety factor specifications in para. 5.2.3.

ASME A90.1:2015 pdf free download