ASME B16.36:2015 pdf free download

ASME B16.36:2015 pdf free download.Orifice Flanges

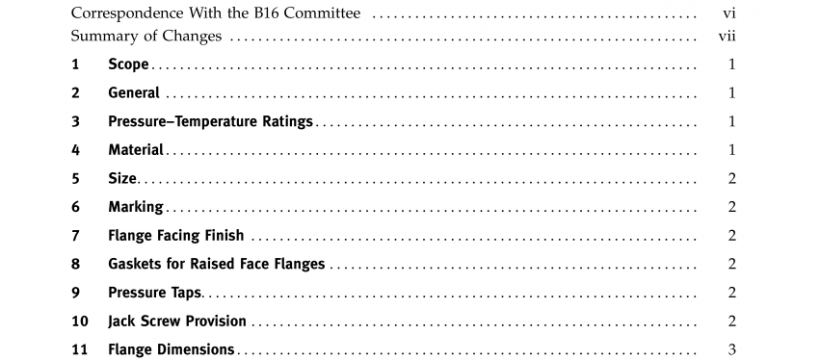

9.1 General

Each orifice flange shall be provided with two pres- sure tap holes extending radially from the outside diam- eter of the flange to the inside diameter of the flange. Corner taps may be used on NPS 1 1 ⁄ 2 and smaller if space permits. See Fig. 1. For ring joint flanges listed in Tables 2 through 5, Tables I-2 through I-5, and Mandatory Appendix II, where radial taps will interfere with the ring groove, angular meter taps, as illustrated in Fig. 2, will be required. Each pressure tap hole shall be equipped with a pipe plug.

9.2 Location

9.2.1 Measurement. The 24 mm(0.94 in.) dimension for raised face and 19 mm (0.75 in.) for ring joint shall be measured at the bore.

9.2.2 Identification. For ring joint flanges requiring alteration of pressure tap location due to interference with the ring groove other than methods provided in this Standard, such alteration shall be identified per agreement between purchaser and manufacturer.

9.3 Pipe Connection Unless otherwise specified, pressure tap holes may be either tapped 1 ⁄ 2 NPT in accordance with ASME B1.20.1 or 1 ⁄ 2 NPS socket connection in accordance with ASME B16.11.

10.1 Location

Each flange shall have a machine bolt mounted in a hole drilled on the flange bolt circle centerline at 90 deg from the pressure taps, for use as a jack screw. The machine bolt shall be regular with one heavy hex nut. See Fig. 3.

12 FLANGE THREADS

Threaded flanges shall have an American National Standard taper pipe thread conforming to ASME B1.20.1.

(a) The thread shall be concentric with the axis of the flange. Variations inalignmentshall notexceed 5 mm/m (0.06 in./ft).

(b) The flanges are made with counterbores at the back of the flange and the threads shall be chamfered to the diameterofthe counterbore atanangle ofapproxi- mately 45 deg with the axis of the thread to afford easy entrance in making a joint. The counterbore and chamfer shall be concentric with the thread.

(c) In order to permit the pipe to be inserted to the face of the flange, the threads should have full root diameters through to the face of the flange, or shall have a counterbore at the face of the flange.

(d) The gaging notch of the working gage shall come flush with the bottom of the chamfer in all threaded flanges and shall be considered as being the intersection of the chamfer cone and the pitch cone of the thread. This depthofchamfer is approximatelyequal to one-half the pitch of the thread.

(e) The maximum allowable thread variation is one turn large or small from the gaging notch.

ASME B16.36:2015 pdf free download