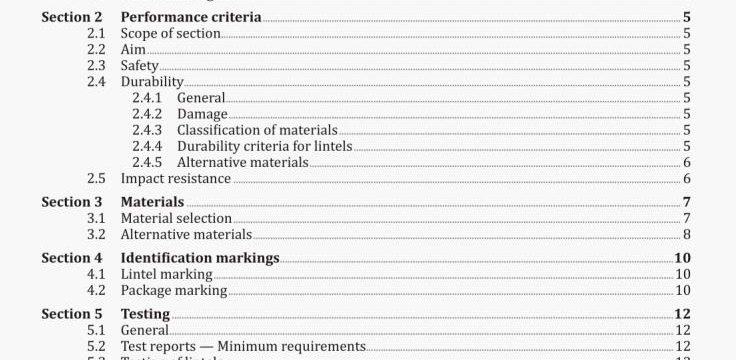

Lintels and shelf angles (durability requirements)

AS 2699.3-2020 pdf download.Built-in components for masonry construction

Part 3: Lintels and shelf angles (durability requirements).

NOTE It is essential that lintels attached to supporting walls be Installed so that they do not permit water transfer across the cavity to the supporting frame. For example, flashing or a drip mechanism may be used to shed water into the cavity.

2.3 Safety

Features that present a safety hazard, e.g. sharp edges and burrs, shall be removed. In the case of coated lintels, these features shall be removed prior to coating.

2.4 Durability

2.4.1 General

Materials for the manufacture of lintels shall be either inherently corrosion resistant or suitably treated to ensure sufficient durability to achieve design life.

2.4.2 Damage

All cut ends and any damaged areas on coated lintels shall be repaired prior to installation to ensure that the durability criteria are met. The minimum acceptable repair requirements and methods shall be in accordance with Appendix F.

2.4.3 Classification of materials

Lintels manufactured from any material shall be identified as durability classes Ri to R5, as defined in

AS 3700, AS 4773.1, and AS 4773.2, by application of the acceptance criteria in Clause 2.4.4.

2.4.4 Durability criteria for lintels

Lintels shall suffer no loss in serviceability over the design life of the structure (see Clause 2.2) when

subjected to the following in-service conditions:

(a) Ri and R2—

(I) all interior locations;

(ii) exterior locations more than 1 km from a non-surf coast and not classed

as industrial;

(lii) exterior locations more than 10 km from a surf coast and not classed as industrial;

(iv) protected exterior locations with a coating above the damp proof course (DPC) or a niembrane below the DPC in any atmospheric environment; or

(v) locations not subject to wetting or soil exposure.

R3 —

(I) exterior locations 100 m to 1 km from a non-surf coast;

(ii) exterior location 1 km to 10 km from a surf coast; or

(iii) exterior locations subject to non-saline wetting and drying.

R4 —

(i) exterior locations less than 100 m from a non-surf coast;

(ii) exterior locations less than 1 km from a su rf coast; or

(iii) exterior locations subject to saline wetting and drying or aggressive soil.

(d) R5: Locations outside the above criteria which show severe corrosion (see Note 2).

The design solutions for the durability criteria of this Clause shall be as specified in Table 3.1.

NOTE 1 Appendix D relates the durability classifications RI to R5 to the Iso 9223 corrosivity categories and locations described in AS 4312—2008.

NOTE 2 Examples of R5 durability class are CX atmospheric environments, acid sulfate soils, enclosed swimming pools, fertilizer sheds, tanneries, chemical plants, piggeries, poultry sheds and similar environments, which may require special materials or coatings

2.4.5 Alternative materials

Where alternative material are used in the production of lintels, conformance to the durability criteria set out in this Standard shall be demonstrated as specified in Clause 3.2.

2.5 Impact resistance

Coatings on lintels shall have sufficient impact resistance to ensure that they remain intact under normal handling conditions expected during manufacture, transportation and installation.

Any damage shall be repaired (see Clause 2.4.2).AS 2699.3-2020 pdf download.

Lintels and shelf angles (durability requirements)