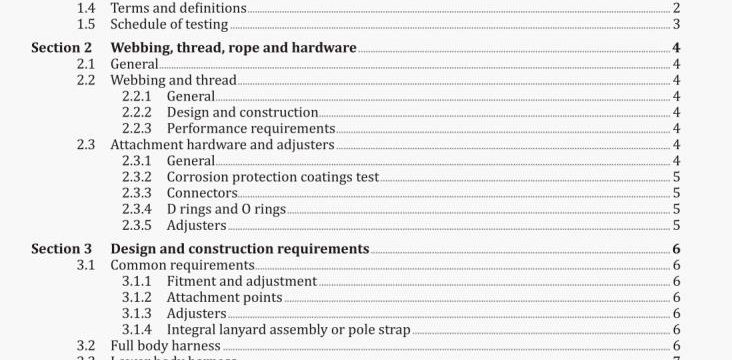

Manufacturing requirements for full body combination and lower body harnesses

AS NZS 1891.1-2020 pdf download.Personal equipment for work at height

Part 1: Manufacturing requirements for full body combination and lower body harnesses.

2.1 General

This Section specifies requirements for webbing, rope, thread and hardware used as a component of a harness.

Natural fibres and materials, other than those meeting the requirements specified in Clause 2.2, shall not be used for load bearing components, but may be used for other purposes such as, but not limited to, wear protection, alignment or padding.

All ancillary, non-load bearing components should be designed to be replaceable or last the life of the harness.

2.2 Webbing and thread

2.2.1 General

All harness load bearing components which distribute force to the body and are in contact with it shall be made from webbing or material equivalent to webbing in respect of strength, durability and load transfer characteristics.

2.2.2 Design and construction

Webbing shall be manufactured from high tenacity synthetic fibre.

The width of the load transfer area of any load-bearing material at any point which distributes the load directly to the body shall not be less than 40 mm wide and shall remain substantially flat In regular use. The load transfer area is the section of the harness in contact with the body.

Holes, rivets or eyelets shall not be used in load bearing webbing.

Threads for sewing load bearing components shall be of a contrasting colour to the webbing.

NOTE The thread should be manufactured from high tenacity synthetic fibre and have a melting point and chemical resistance equivalent to or superior to the material being sewn.

2.2.3 Performance requirements

Loadbearing webbing shall be tested in accordance with Appendix A for resistance to degradation by either artificial light or daylight.

When tested in accordance with Appendix A the minimum breaking strength of the three exposed samples shall be at least 70% of the mean of the breaking strength of the three unexposed samples.

2.3 Attachment hardware and adjusters

Metal components shall be coated for corrosion protection and tested in accordance with ISO 9227, neutral salt spray (NSS) test, with 24 h testing + 1 h drying + 24 h testing + 1 h drying and examined within 90 s after drying.

Following testing —

(a) products with moving parts shall still function as designed; and

(b) there shall be no loss of the protective coating which exposes underlying base material.

NOTE Tarnishing and discolouration is acceptable.

2.3.3 Connectors

Connectors shall be in accordance with either —

(a) ANSI/ASSP Z359.12; or

(b) EN 362.

Connectors conforming with EN 362 shall also have a gate resistance (face and side) of 6 kN minimum.

2.3.4 D rings and 0 rings

D rings and 0 rings used as attachment hardware shall have a minimum capacity of 22 kN.

Testing shall be in accordance with ANSI/ASSP Z359.12.

Products being used to perform the same function as a 0 ring or 0 ring, manufactured from rigid material other than metal, shall meet the same requirements specified in Clauses 2.3.1, 2.3.2 and this Clause 2.3.4.

2.3.5 Adjusters

Adjusters shall be designed —

(a) such that they can be fastened only in the intended manner;

(b) to withstand the loads transmitted as a result of the appropriate assembly test (see Appendices B to E as applicable); and

(c) to withstand, without permanent distortion, a load of S kN for 3 mm when tested in accordance with the methodology specified in ANSI/ASSP Z359.12.

NOTE The design of the adjuster should minimize ‘creep’ of the harness under normal wearing, i.e. cyclic mild tensioning.AS NZS 1891.1-2020 pdf download.

Manufacturing requirements for full body combination and lower body harnesses