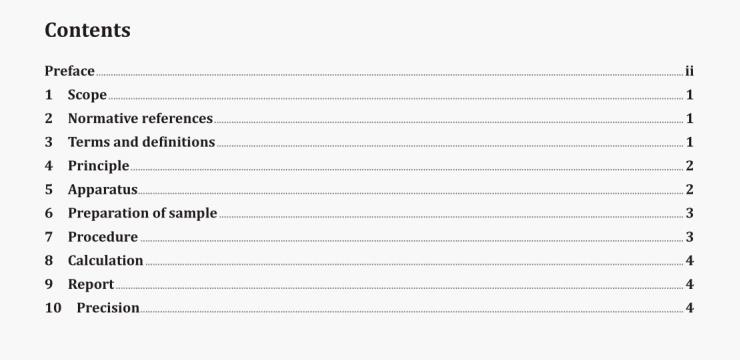

AS 2341.26-2020 pdf download.Methods of testing bitumen and related roadmaking products

Method 26: Determination of sieve residue.

This AS 2341.26 sets out a method for determining the quantity of coarse particles in a bituminous emulsion sample that is retained on a specified sieve. It is applicable for use with conventional bituminous emulsions, high binder content bituminous emulsions and polymer modified bituminous emulsions that have sieve residue results of less than or equal to 1 %.

WARNING — THE USE OF THIS STANDARD MAY INVOLVE HAZARDOUS MATERIALS, OPERATIONS

AND EQUIPMENT. THIS STANDARD DOES NOT PURPORT TO ADDRESS ALL OF THE SAFETY

ISSUES ASSOCIATED WITH ITS USE. IT IS THE RESPONSIBILITY OF THE USER OF THIS STANDARD

TO ESTABLISH APPROPRIATE SAFETY AND HEALTH PRACTICES, AND TO DETERMINE THE

APPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document.

NOTE Documents referenced for informative purposes are listed in the Bibliography.

AS/NZS 2341.1, Methods of testing bitumen and related roadmaking products, Part 1: Precision data

— Definitions

AS/NZS 2341.21, Methods of testing bitumen and related roadmaking products. Method 21:

Sample preparation

ISO 33 10-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

3 Terms and definitions

For the purposes of this document, the terms and definitions in AS/NZS 2341.1 and the following apply.

3.1

bituminous binder

binder predominantly comprised of bitumen

3.2

bituminous emulsion

dispersion of one liquid within another where the dispersed phase is usually a bituminous binder and the continuous phase is usually water

3.2.1

anionic bituminous emulsion

type of bituminous emulsion in which the bituminous binder particles are negatively charged

3.4

shall

indicates that a statement is mandatory

3.5

should

indicates a recommendation

4 Principle

A bituminous emulsion is strained through a weighed sieve to quantify the presence of coarse binder particles that may indicate adverse storage, handling or application effects.

5 Apparatus

The following apparatus is required:

(a) Balance — A balance of at least 200 g capacity, readable to 0.00 1 g, with a limit of performance not exceeding 0.003 g.

(b) Sieve — A sieve, conforming with ISO 3310-1, fitted with a wire mesh having an aperture of either 150 pm or 710 pm. The frame of the sieve should be about 100 mm diameter and 40 mm deep.

NOTE 1 A 710 pm sieve should be used if a high binder content bituminous emulsion or a polymer modified bituminous emulsion is tested.

(c) Sieve tray — Watch glass, or circular metal dish with raised edges, with a diameter larger than the diameter of the sieve used in the test. The sieve tray should be of sufficient size so that the sieve can be placed stably on the sieve tray. The sieve tray should also be of suitable size so that it can be placed on the balance and weighed.

(d) Container — Glass conical flask or beaker, or a plastic disposable cup, of suitable size to weigh the bituminous emulsion sample prior to passing it through the sieve.

(e) Surfactant solution — An aqueous solution of surfactant compatible with the emulsion.

NOTE 2 II available from the supplier, the surfactant solution that was used to produce the emulsion should be used In the test. If such a solution Is not available, then an aqueous solution containing 1 % w/w of cetrimide (a mixture of alkyltrimethylammonium bromides) in 0.1 mol/L HCI has been found to be suitable for testing cationic bituminous emulsions. An aqueous solution containing a suitable anionic surfactant has been found to be suitable for testing anionic bituminous emulsions.

(f) Plastic wash bottle — A wash bottle to store the surfactant solution.AS 2341.26-2020 pdf download.Methods of testing bitumen and related roadmaking products

Methods of testing bitumen and related roadmaking products