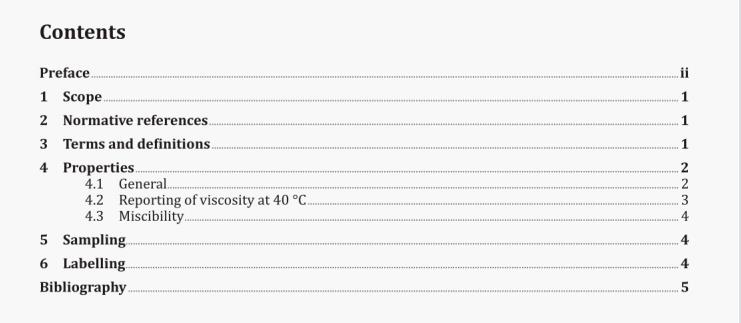

AS 3568-2020 pdf download.Oils for reducing the viscosity of bituminous binders for pavements.

This AS 3568 sets out the requirements for hydrocarbon oils, derived from refined crude petroleum, to be used for reducing the viscosity of bituminous binders in sprayed sealing work and the preparation of bituminous cold mixes.

WARNING — THE USE OF THIS STANDARD MAY INVOLVE HAZARDOUS MATERIALS, OPERATIONS

AND EQUIPMENT. THIS STANDARD DOES NOT PURPORT TO ADDRESS ALL OF THE SAFETY

ISSUES ASSOCIATED WITH ITS USE. IT IS THE RESPONSIBILITY OF THE USER OF THIS STANDARD

TO ESTABLISH APPROPRIATE SAFETY AND HEALTH PRACTICES, AND TO DETERMINE THE

APPLICABILITY OF REGULATORY LIMITATIONS PRIOR TO USE.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements.

N0TF Documents referenced for informative purposes are listed in the Bibliography.

AS 2106.2, Methods for the determination of the flash point of flammable liquids (closed cup), Part 2:

Determination offlash point — Pensky-Martens closed cup method

AS/NZS 2106.1, Methods for the determination of the flash point offlammable liquids (closed cup), Part 1:

Abel closed cup method

ISO 13736, Determination offlash point — Abel closed-cup method

ASTM D86, Standard test method for distillation of petroleum products and liquid fuels at atmospheric pressure

ASTM D93, Standard test met hods for flash point by Pensky.Martens closed cup tester

ASTM D445, Standard test method for kinematic viscosity of transparent and opaque liquids (and calculation of dynamic viscosity)

ASTM 01298, Standard test method for density, relative density, or API gravity of crude petroleum and liquid petroleum products by hydrometer method

ASTM D4052, Standard test method for density, relative density, and APi gravity of liquids by digital density meter

DE F STA N 91-091, Turbine fuel, kerosene type, let A-i: NATO Code: F-35: joint Service Designation: A VTUR

I P 170, Determination offlash point — Abel closed-cup method

JIG, Aviation fuel quality requirements for jointly operated systems (AFQRJOS).

3.5

flux oil

petroleum distillate used to reduce the viscosity of a bituminous binder over a longer period than cutter oil or high flash point cutter

3.6

high flash point cutter

light petroleum distillate similar to cutter oil which has a higher flash point than cutter oil

3.7

may

indicates the existence of an option

3.8

polymer modified binder

PM B

bituminous binder produced by modifying bitumen with a natural or synthetic polymer, or crumb rubber

3.9

shall

indicates that a statement is mandatory

3.10

should

indicates a recommendation

3.11

sprayed sealing work

work that includes pnming. initial sealing and sealing 01 pavements using bituminous binders

4 Properties

4.1 General

The properties of cutter oil shall either—

(a) conform with the requirements of Table 1 when determined in accordance with the methods of test specified in Table 1; or

(b) conform with the requirements for Jet A-i aviation fuel in DEF STAN 91-091 or jIG AFQRJOS.

The properties of high flash point cutter shall conform with the requirements of Table I when determined in accordance with the methods of test specified in Table 1.

4.3 Miscibility

Cutter oil, high flash point cutter and flux oil shall be completely miscible with bitumen. No precipitation

shall occur when mixed with a bituminous binder.

5 Sampling

Oils shall be sampled so as to obtain a representative sample oIthe larger quantity of oil from which the sample is obtained.

NOTE The methods described in ASTM D4057 for obtaining representative samples may be used.

6 Labelling

Samples shall be firmly packed for transport to the testing laboratory. They shall be clearly identified

by markings on the body of the container.

The following information shall be shown on the container or label:

(a) Product name or description.

(b) Identification mark or batch number.

(c) Date and time of sampling.

(d) Supplier.

(e) Place of sampling.

(f) Quantity of material represented by sample where known.

(g) Type and identifying number of container or vehicle from which the sample was taken.

(h) Name of the sampler.AS 3568-2020 pdf download.Oils for reducing the viscosity of bituminous binders for pavements

Oils for reducing the viscosity of bituminous binders for pavements