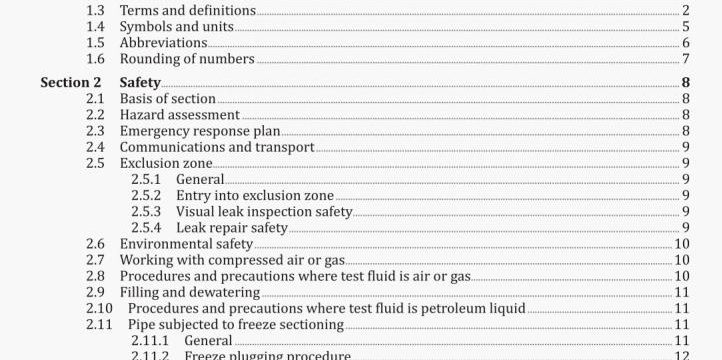

Pipelines – Gas and liquid petroleum

AS 2885.5-2020 pdf download.Pipelines – Gas and liquid petroleum Part 5 : Field pressure testing.

2.2 Hazard assessment

Prior to conducting a pressure test, a formal hazard assessment shall be undertaken using an appropriate methodology to identify hazards, failure modes, controls, and to assess residual risks.

The TEST PLAN or the test procedure or both shall be included in this assessment.

The hazard assessment shall consider the consequence of pipeline failure at any point along the length of the test section, particularly at locations where the failure may impact on the public, public facilities, or the environment. If necessary, additional controls shall be applied to manage this risk.

The TEST SIGNATORY shall participate in, and endorse, the hazard assessment.

NOTE 1 For the safety management requirements for a new or an existing pipeline, refer to AS/NZS 2885.1, AS/NZS 2885.3 and AS/NZS 2885.6. An SMS does not replace the field pressure testing hazard assessment. The safety management requirenients, for example hazard control methods applied to the design and the field-testing procedures, should be considered in the field-testing procedures and provided to the TEST SIGNATORY.

NOTE 2 One method for reducing risk in areas where failure may impact public, facilities or personnel is to apply the concept of PRELIMINARY TESTS in areas such as road or rail crossings and pipeline sections within manned facilities.

The hazard assessment shall be performed prior to commencement of testing operations to consider the sources of potential harm specific to pressure testing. It shall encompass each aspect of the testing operation and consider the safety of testing personnel, other construction personnel, general public, landholders and any other stakeholders.

The hazard assessment and the method used to conduct the hazard assessment shall be documented. NOTE 3 For further information on safety in pressure testing, see Appendix N.

2.3 Emergency response plan

An emergency response plan shall be prepared for the pressure test. The plan shall address at least the following:

(a) Risk (or hazard) management in place for the test. This will be different for a new pipeline being tested as part of a construction operation than for an in-service test of an existing pipeline.

(b) Emergency events identified from the hazard assessment.

(c) Communication with public authorities and key stakeholders such as landowners.

(d) Personnel safety and response, including medical evacuation.

(e) Environmental response.

2.5.1 General

The EXCLUSION ZONE shall be determined for each test section.

The method by which exclusion is used as a hazard control and the method by which the EXCLUSION ZONE will be communicated with personnel and the public shall be nominated in the TEST PLAN. The effectiveness of these methods shall be assessed in the hazard assessment.

Where the EXCLUSION ZONE is not an effective control (e.g. at crossings and in populated areas). alternative controls shall be identified and applied.

A separate EXCLUSION ZONE shall be prepared for personnel protection against asphyxiation during freeze plugging operations.

NOTE Appendix N provides guidance on methods for assessing the dimensions of the exclusion zone.

2.5.2 Entry Into exclusion zone

Only personnel directly involved in testing operations shall be permitted to enter the EXCLUSION ZONE. Each entry shall be authorized.

Personnel shall not enter the EXCLUSION ZONE during pressurization.

Personnel shall not enter the EXCLUSION ZONE while the test section is at full STRENGTH TEST pressure unless the hazard has been assessed and appropriate controls have been provided to reduce the risk to the testing personnel to as low as reasonably practicable (ALARP).

Where there is a risk of failure when pressure is greater than the MILL TEST PRESSURE, the pressure shall be reduced by not less than 10 % of current test pressure prior to entry being authorized.

2.5.3 VIsual leak Inspection safety

The safety of personnel conducting a visual inspection during a STRENGTH TEST shall be addressed in the hazard assessment. Controls shall be developed to ensure personnel safety during visual inspection.

NOTE lithe test pressure for a visual-type test exceeds the pipe MILL TEST PRESSURE, the STRENGTH TEST pressure should be maintained for 2 h with no access by personnel within the EXCLUSION ZONE. Upon completion of the HOLD PERIOD, the test pressure should be reduced by 10 % and maintained for a sufficient time to facilitate visual inspection for leaks.

2.5.4 Leak repair safety

Leak repair methods shall consider the safety aspects of the repair process.

NOTE 1 Flange bolts and hammer unions should be tightened using the correct tools. Flogging-up methods should not be used.AS 2885.5-2020 pdf download.

Pipelines – Gas and liquid petroleum